Plastic Injection Blow Molding Machine

We specialize in manufacturing injection blow molding machines for high-quality plastic bottle production.

Introduction: IBM Injection Blow Molding Machinery

-

1. Inverted Head

IBM Inverted Head Injection blow mold machinery is the most popular range of IBM blow molding machines because all hydraulics are situated beneath the mold in the base of the machine. The Injection Blow Molding Machinery system is fool proof and does not allow oil from the hydraulics to contaminate the mold or the finished product. The machine has the added advantage of using a pull down tie-bar system which is excellent for large cavitations used in the 135 Ton and 189 Ton range. The alternative is hydraulics above the mold where leaking may occur, thus contaminating the mold area. Furthermore, applying pressure more to the center of the mold than the pull down outside tie bars often inhibits the complete formation of the outer molds because of flexing. Large machines of the non-inverted head type, also are susceptible to frame cracking because of the flexing. A full range of plastic molding machines are available: From 60 Ton to 250 Ton.

Inverted Head Can Mold Machines (Complete Program)

Pet All also offers full IBM Molds and Tooling. The equipment has been specially designed for Pet All Manufacturing Inc., and all machines for the North American market are tested and approved at our engineering center before release to customers. We have been a renowned injection blow molding machine manufacturer and supplier in North and South America and Europe, with over 40 years of experience.

- Model 250/450 (50 Ton)

- Model 300/700 (78.6 Ton)

- Model 700/1200 (135 Ton)

- Model 700 / 1600 (189 Ton)

- Model 700 / 1900 (205 Ton)

- Model 800 / 200 (220 Ton)

The Can Mold Inverted Head (upside down hydraulics) brand machines have the following outstanding features:

- Heavy duty solid construction

- Oil-free components in the sector above the take-off conveyor giving added suitability for use in pharmaceutical and delicate cosmetic containers

- Screw and barrel composition: The screw is made of high quality 38 CrMoA1A material and is hard plated to 40Cr. The barrel is made of high quality bearing steel and is spray welded with hard alloy.

- The machines come complete with all-round security guarding which is shown in the photographs, and meet OSHA specifications.

- Oil Pump Vickers & Parker Denison (USA)

- Hydraulic valves Vickers (USA)

- Pneumatic valves Festo (Germany)

- Control computer Mitsubishi & Omron (Japan)

- Switch Omron (Japan)

- Transducers Gefran (Italy)

- Displays Allen Bradley (USA)

- Low-tension wiring Schneider (France)

- Oil motor Intermot (Italy)

- Electromotor Bijie (China)

- Mold temperature control Shini (China)

- Screw and barrel Jinyou (China)

- Working table Cast Iron

Benefits of Inverted Head Design:

- Reduced Contamination Risk: The inverted head design plastic molding machine positions the hydraulics below the mold, eliminating the risk of oil leaks contaminating your product or mold. This is crucial for industries like food and beverage or pharmaceuticals, where product purity is essential.

- Improved Mold Formation: The pull-down tie-bar system in inverted head machines applies clamping force directly to the center of the mold. This minimizes flexing and ensures proper mold closure, leading to better part quality and fewer rejects.

- Suitable for Large Molds: The inverted head design in plastic injection blow molding machine offers superior clamping force distribution, making it ideal for handling large molds to produce big containers or bottles. This allows for efficient high-volume production.

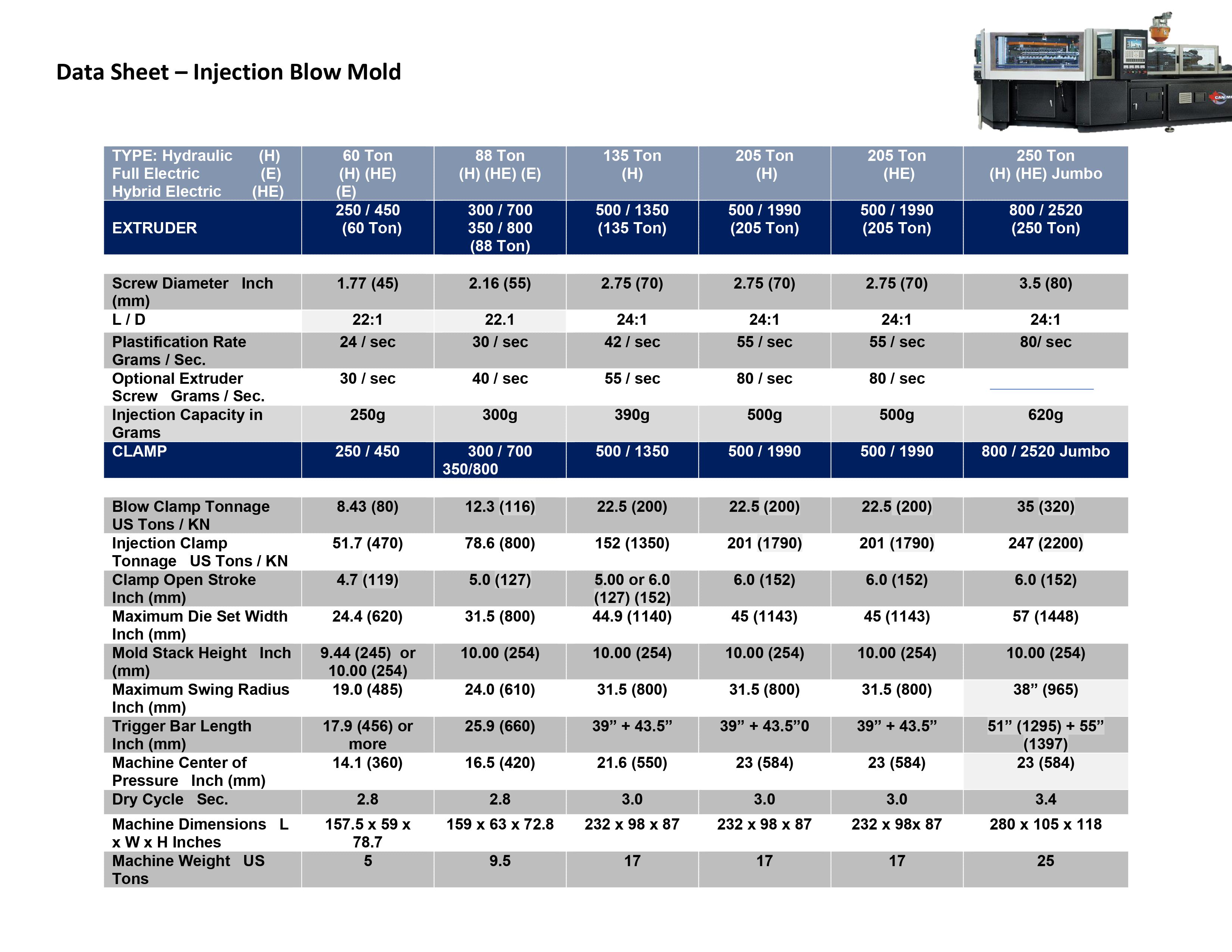

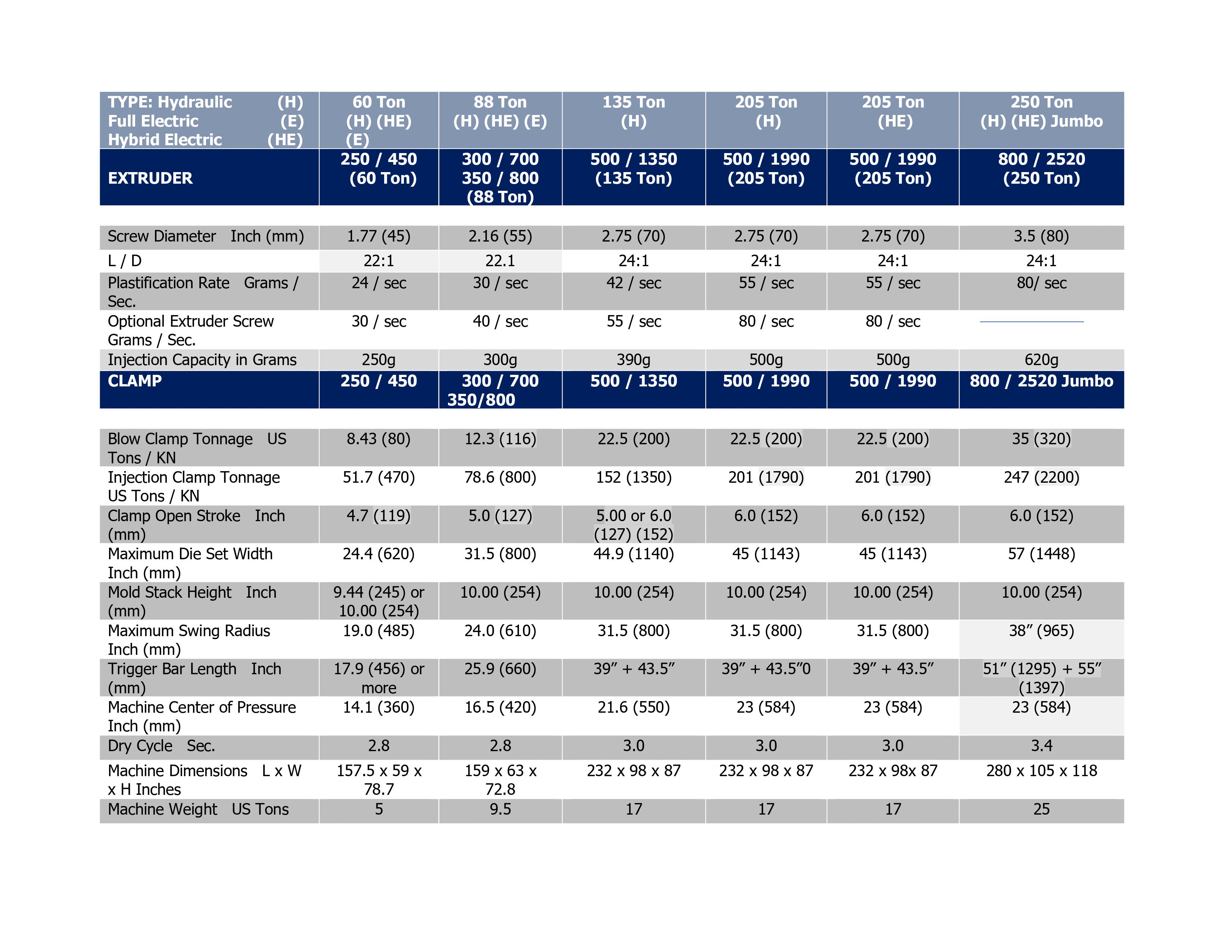

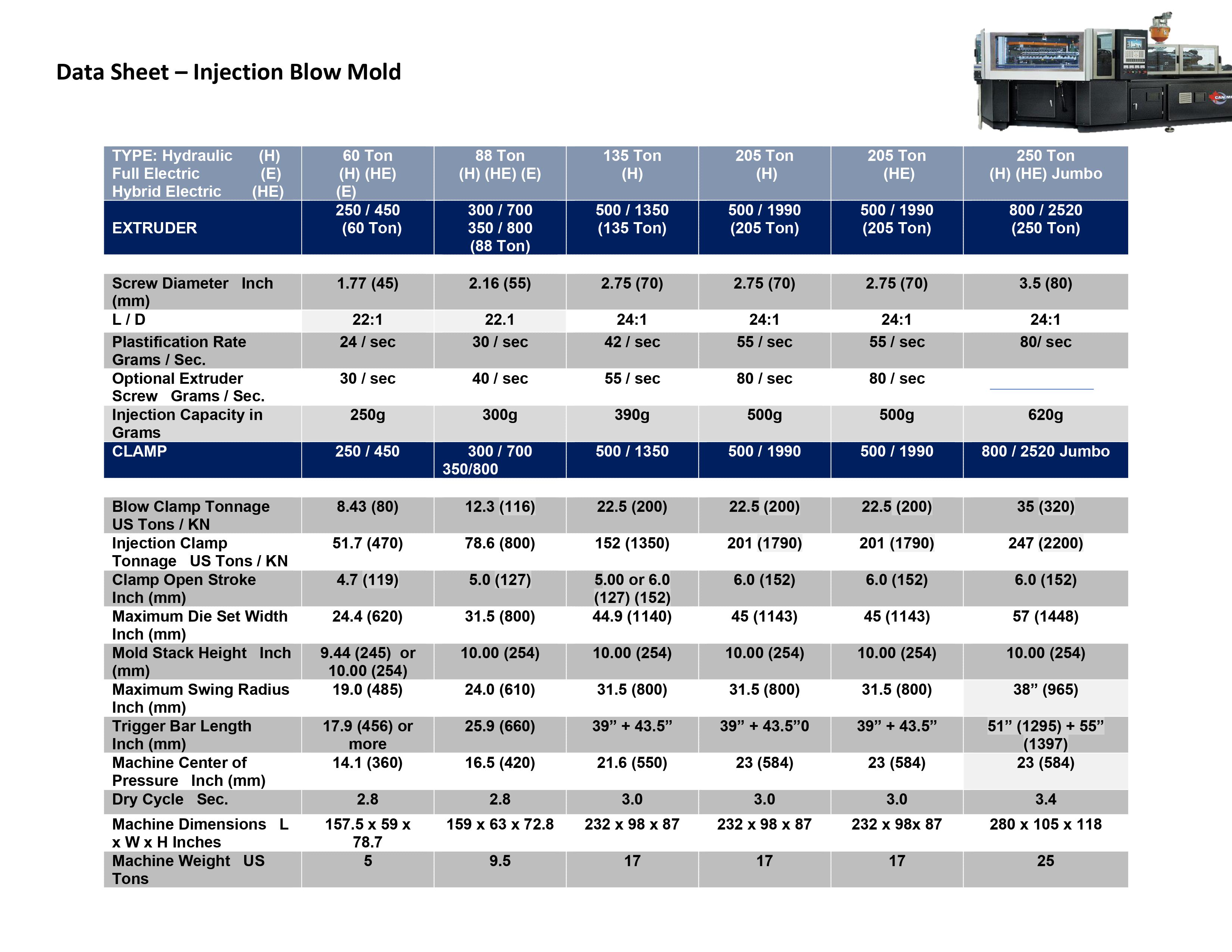

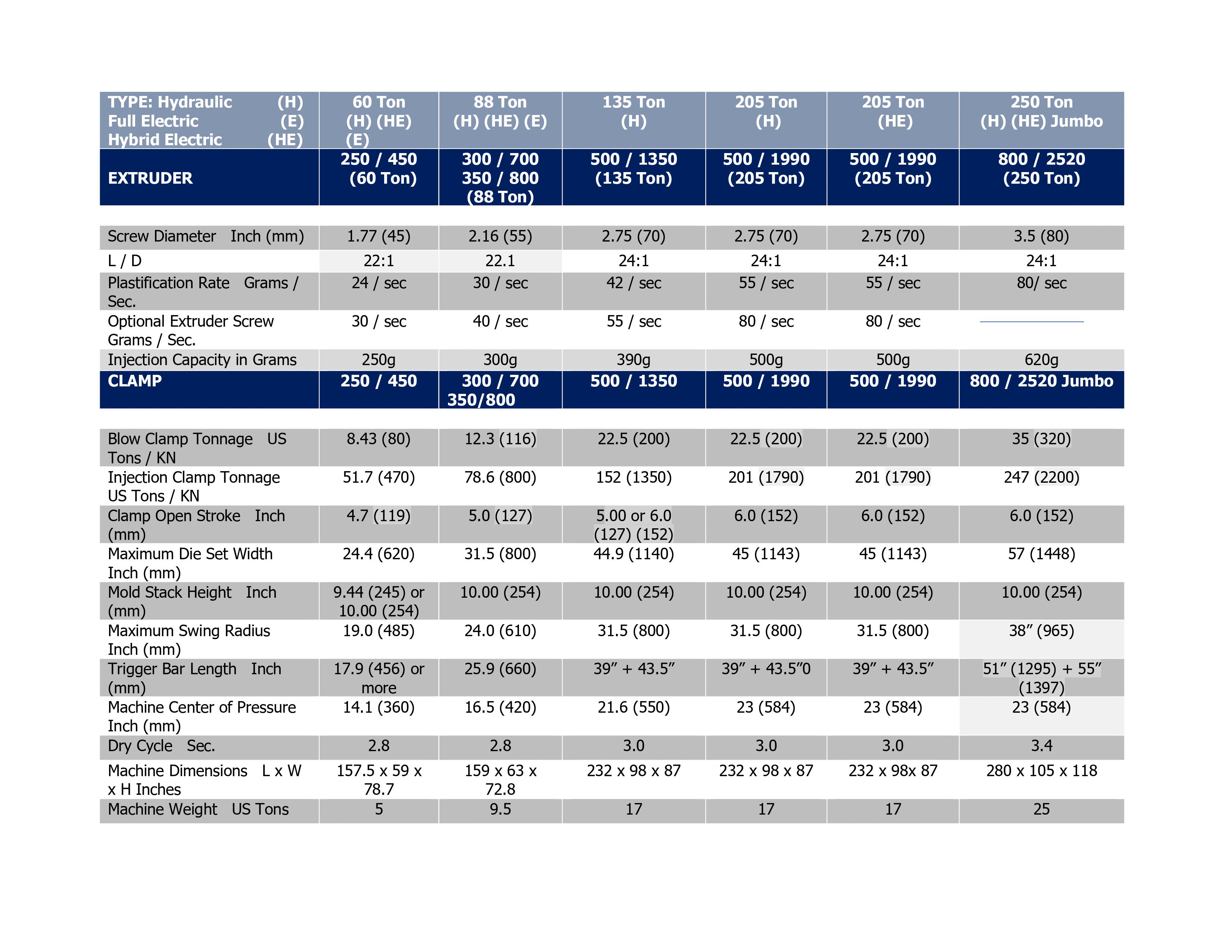

Product Sizing for Injection blow molding machine Bottles

Please see the chart below of Injection blow molding Machinery product sizing of bottles for each size of body/diameter etc. These are good estimates only.

Product Size IBM 250/450

60 TonIBM 300/700

88 TonIBM 700/1200

135 TonVolume Neck Dia Height Body Dia Cavities Cavities Cavities 5ml 10 35 15 14 22 30 10ml 12 40 20 12 20 30 20ml 15 50 25 10 18 28 30ml 20 60 30 9 16 26 40ml 22 65 35 8 14 24 60ml 28 75 40 8 13 22 80ml 30 80 45 7 12 20 100ml 32 85 50 6 12 20 150ml 35 90 53 5 10 18 200ml 38 100 58 4 8 16 400ml 42 120 65 3 6 12 650ml 50 160 80 2 5 10 1000ml 40 200 90 4 8 1500ml 45 200 103 3 6

Deodorant stick first developed by ADOP, France

Established in 1989 Pet All has been an injection blow molding machine manufacturer, offering a wide range of plastic molding machines in the US market.

- 2. Inverted Head Hybrid

- 3. Inverted Head Full Electric

Injection blow molding, typically 2 oz to 16 oz bottles in PP or HDPE. These machines make preforms and bottles in the same machine

- Model: 135 Ton IBM

Please click on this YouTube video link to view a machine running in full production: Click Video Now

Pet All’s line of IBM Injection Blow Mold Machines produce high quality containers and quicker ROI.

There are several advantages in using injection blow. In injection blow molding the part is formed in an enclosed mold and there is no scrap to be trimmed from the container. The IBM process allows for the formation of a thick treaded neck with a thin container wall. This feature allows for the use of injection blow molding for safety enclosures for pill bottles.

Process: Injection Blow Molding

What our clients say!

Recommendation for PetAll Injection Blow Machines

Mike,

Please use this email as my recommendation for the PetAll Can Mold Injection Blow Molding machines. My experience with these machines has been nothing short of exceptional. Below is a summary of my experience with PetAll and your Can Mold machines.

1. In my role as VP Business Unit Manager of O-I Health Care Packaging my team of engineers conducted a side by side comparison of your Can Mold IBM machines to the industry standard Uniloy and Jomar machines. In all tests the Can Mold machines performed as good as or better in process reliability, dependability and durability. As a bonus capability the cost for these Can Mold machines is significantly less than the industry standard machines.

2. In my role as President of Priority Plastics we installed 9 of the PetAll Can Mold machines and the machines performed at the same exceptional level as the machines did when tested and run at O-I.

3. In my 25+ years’ experience in working with PetAll I have nothing but praise for the quality of your equipment, service levels and most importantly high level of integrity. You have always delivered what you said you would and if ever a problem arose you were first in line to address and correct the problem, regardless of whose fault it was.

Please keep in mind that the IBM process is still a process and engineers as well as the operators must be capable. The staffs at O-I and Priority (while I was in the leadership role) were considered industry leaders in their fields so our experience with the PetAll Can Mold machines was exceptional. One can take an exceptional machine with poor operators and achieve poor results. So if anyone in the industry does not share my evaluation and experience with the PetAll Can Mold machines I would look at the operator and management capabilities of the company and NOT the machines.

Please feel free to use this recommendation as you see fit. I stand behind my evaluation (and a team of industry experts) and the many months of gathering engineering and performance data on your machines and the process capabilities of your machines.

Sincerely,

William P Negrini

Former OI Health Care Packaging VP Business Unit Manager

-

Parts

- Now you can order parts directly from our website's home page by clicking on the "Parts Inquiry" button.

- Pet All continues to fulfill all spare part needs, and we take pride in doing so in a timely manner.

- Our shipping and logistics partners ensure no significant delays are incurred, minimizing downtime and costs.

-

Reliable Technical Support

- Pet All offers 24/7 phone and online technical support.

- Pet All's technicians travel around the globe to make sure our customers are always happy.

- Included with all machines: Phone, in person, on site, teleconference troubleshooting and diagnostics technical support and service.

- Parts and in house service are included in the life of all Pet All machine warranties.

-

Sales Support

- Our team is always available to provide information, answer questions, or schedule machine demonstrations.

- Quotes are always complimentary

Pet All Manufacturing Inc. manufactures and supplies plastic injection blow molding machines in North America, Latin America, and Europe.